Subsea 7 awarded contract offshore Norway

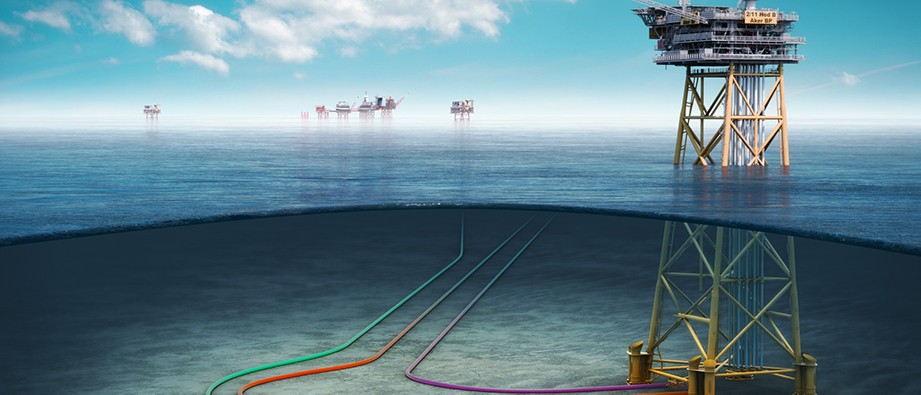

Subsea 7 today announced the award of a sizeable(1) contract by Aker BP for the Hod Field Development Project, located 12 km from the Valhall area in the southern part of the North Sea.

The re-development concept includes a new Wellhead platform (Hod B) tied back to Valhall Field Centre with rigid pipelines and an umbilical.

The contract scope includes EPCI for pipelines, umbilicals and tie-ins using key vessels from Subsea 7’s modern fleet. The production pipeline is a pipe-in-pipe design and will include the world’s first application of mechanically lined pipe based on GluBi® (2) technology from BUTTING.

Project management and engineering will commence immediately at Subsea 7’s offices in Stavanger, Norway. Fabrication of the pipelines will take place at Subsea 7’s spoolbase at Vigra, Norway and offshore operations will take place in 2020 and 2021.

Monica Bjørkmann, Vice President for Subsea 7 Norway said: “Subsea 7 is very pleased with this award by Aker BP, through the Aker BP Subsea Alliance. It acknowledges Subsea 7 as a key partner in the delivery of pioneering technology, transforming the economics of field development. We look forward to continuing our alliance with Aker BP for the Hod Field Development, with safety, reliability and quality at the forefront throughout.”